NOROO R&C

About Us

Products

Customer Support

PRODUCT

On-line catalogue

Automotive Coatings [Resin]

1. Leather

- WA 2045

- WUI 1300

- WUI 03652. Finishing plastics (bumper, side mirror, reflector)

- AC 0583

- WA 20003. Interior plastics

- AC 3527

- AC 35284. Finishing body (electro coating, base, clear)

- AC 0515

- WU 4200

- WUI 1932

- WA 0330

Major Resin Products

| Resin type | Product name | Main characteristics | Main usage |

|---|---|---|---|

| THERMOSETTING ACRYLIC RESINS | AC 0515 | Chemically resistant, mechanical characteristics, high exterior quality, natural drying | Automotive maintenance 2K top coating/top coating transparent |

| THERMOPLASTIC ACRYLIC RESINS | AC 0583 | High hardness, high gloss, quick drying | Automotives, plastics |

| THERMOPLASTIC ACRYLIC RESINS | AC 3527 | Chipping-resistant, chemically resistant, high gloss, thickness, good exterior | Automotives, plastics |

| THERMOPLASTIC ACRYLIC RESINS | AC 3528 | Chipping-resistant, chemically resistant, high gloss, thickness, good exterior | Automotives, plastics |

| Dispersion | WUI 0365 | Soft feel, adhesiveness | Leather top coating, textile |

| Dispersion | WUI 1300 | Pliability, soft feel | Leather (mid-quality), textile |

| Dispersion | WUI 1932 | Chipping-resistant, non-xanthocramatic, adhesiveness | Automotives let-down, plastics, metal |

| Dispersion | WU 4200 | High gloss, chemically resistant, mechanical characteristics | Automotive maintenance mid-coating, plastics |

| ACRYLIC EMULSION | WA 2000 | Core-shell type | Plastics (bumper), finishing material mid-coating |

| ACRYLIC EMULSION | WA 2045 | Adhesiveness | Leather |

| Waterborne acryl polyol | WA 0330 | Water dispersion acryl, emulsifier-free, water-resistant, high gloss | Automotive maintenance, plastics, metal |

Technical materials are provided in a pdf file for a technical question to staff in charge.

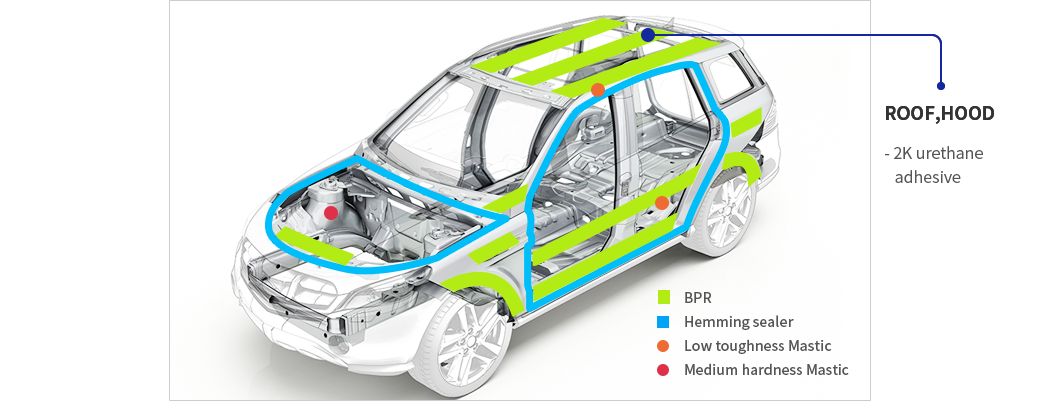

Automotive Use [Adhesives]

Major Adhesive Products

| Classification | Product name | Applied part | Main component | Basic attributes | Characteristics of product | ||

|---|---|---|---|---|---|---|---|

| Thermosetting TYPE |

Automotive coatings | BPR (Body PanelReinforcement) |

Door, trunk lid, outer body’s vulnerable parts | EPOXY | - Shear strength: 88kgf/㎠ or over - Bending strength: 5.5Kgf±0.5 |

The product simplifies production processes with a hard stiffener, which allows spraying. A thermosetting product applied to add hardness and pliability to exterior body and provide rust-resistance, hardness and dust-proof. | |

| MASTIC (Anti-flutter) |

Low toughness | Door, roof inner and outer body filling | RUBBER | - Shear strength: 2~4 kgf/㎠ - Foaming rate: 40%±3 |

A thermosetting product to attach outer body, impact bar and shim plate providing rust-resistance, dust-proof, and sound-proof. | ||

| Medium hardness | Hood, trunk inner and outer body filling | RUBBER | - Shear strength: 5~8kgf/㎠ - Foaming rate: 30%±3 |

||||

| Adhesives for structure | D TYPE | High toughness adhesive to spray on the attachment part of automotive steel plates, reducing or eliminating spot welding. | EPOXY | - Shear strength: 25㎫ or over - Impact strength: 35N/mm or over |

High toughness adhesive to replace or reduce spot welding by applying to the parts where steel plates are overlapping. High toughness thermosetting adhesive applied to improve rust-resistance, hardness and impact reliability by stabilizing the structure with stress distribution and adhesiveness on a uniform plate. | ||

| E TYPE | - Shear strength: 30㎫ or over - Impact strength: 45N/mm or over |

||||||

| Hemming sealer | C TYPE | Door, hood, trunk lid hem flenge part | EPOXY | - Shear strength: 20㎫ or over | High hardness thermosetting product applying to hemming parts where steel plates are overlapping at outer and inner panels of door, hood, and trunk lid which does not allow spot welding; or those parts which require high adhesive toughness such as welding or mechanical bond. | ||

| D TYPE | - Shear strength: 20㎫ or over - Impact strength: 35N/mm or over |

||||||

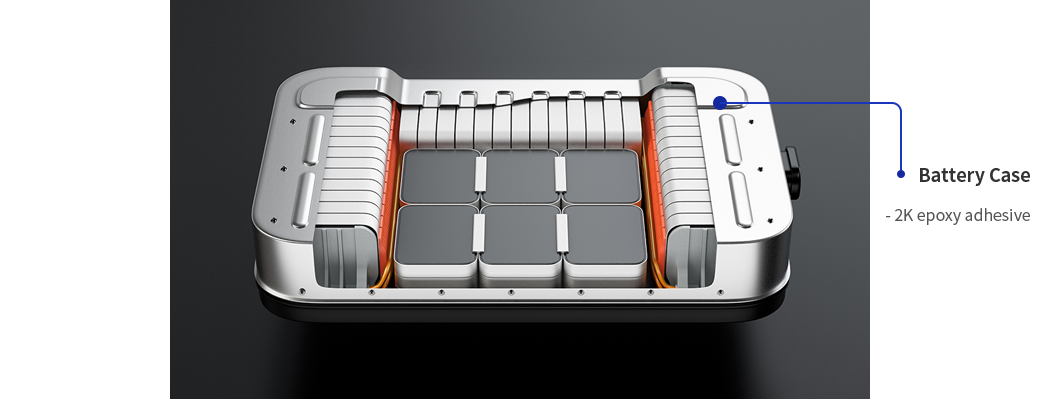

| Room temperature setting TYPE |

Assembly Automotive body |

Two compound epoxy adhesive | Attaching various materials such as metal, ceramic, plastics, etc. | Epoxy | -전단강도 • Steel : 20㎫ or over • Aluminum : 17㎫ or over |

Room temperature setting product, which applies, to automotive areas and especially to battery case, providing excellent adhesiveness and water proof. | |

| Painting | Two compound urethane adhesive | Attaching various plastics, composite materials and painting parts. | Urethane | - Shear strength: 15㎫ or over - Dispersion rate: 70% |

Room temperature setting product with excellent attachment for dissimilar materials such as automotive painting parts after surface pre-treatment, plastics and composite materials. | ||

GO to Top